Single-ply commercial roofing systems are popular due to their durability, ease of installation, and cost-effectiveness. The three main types of single-ply roofing systems are Thermoplastic Olefin (TPO), Ethylene Propylene Diene Monomer (EPDM), and Polyvinyl Chloride (PVC). Each single-ply roofing membrane has its own set of characteristics, advantages, and disadvantages.

Types of Single Ply Roofing Systems

Let’s explore each single-ply roofing system so you can consider the pros and cons of each before meeting with your commercial roofing contractor.

TPO Roofing Systems

TPO is made from a blend of rubber, polypropylene, and reinforcing filler materials.

Here are a few advantages of TPO membrane roofing systems.

- TPO membranes are highly resistant to UV radiation, ozone, and chemical exposure.

- The flexible sheets can accommodate building movement.

- TPO roofs are typically white or light-colored, which helps reflect sunlight, reducing cooling costs.

Because quality control can vary between manufacturers and lead to inconsistencies in TPO performance, it’s essential that you work with an expert commercial roof contractor known for high-quality installation and materials.

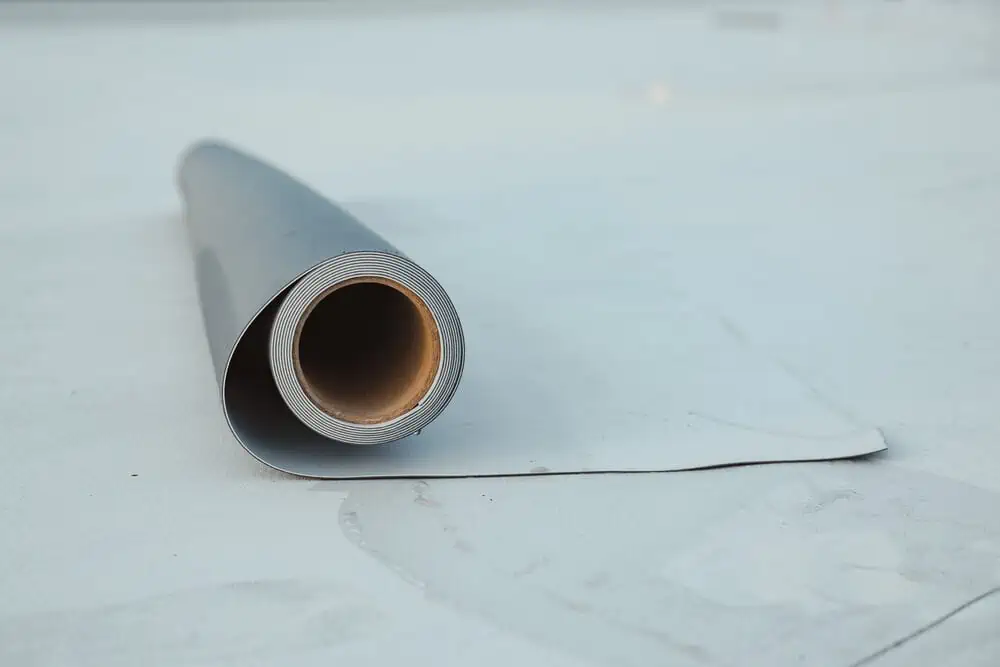

EPDM (Ethylene Propylene Diene Monomer) Single Ply Roofing System

EPDM is a synthetic rubber material derived from ethylene, propylene, and diene monomers. There are many advantages of this type of single-ply membrane roof.

- EPDM roofs have a proven track record in the commercial roofing market as durable and long-lasting single-ply roofing membranes.

- They are highly resistant to weathering, UV radiation, and thermal shock.

- EPDM membranes are relatively easy to repair and maintain.

While these systems are widely used, EPDM roofing systems are sometimes considered less resistant to punctures and tears than other single-ply membranes.

PVC (Polyvinyl Chloride)

PVC is a single-ply roof system made of synthetic plastic material containing chlorine, ethylene, and additives for flexibility and stability. PVC roofing material has many advantages.

- PVC membranes offer excellent resistance to chemicals, grease, and oil.

- They have superior fire resistance compared to other single-ply membranes.

- PVC roofs are highly durable and have a long service life.

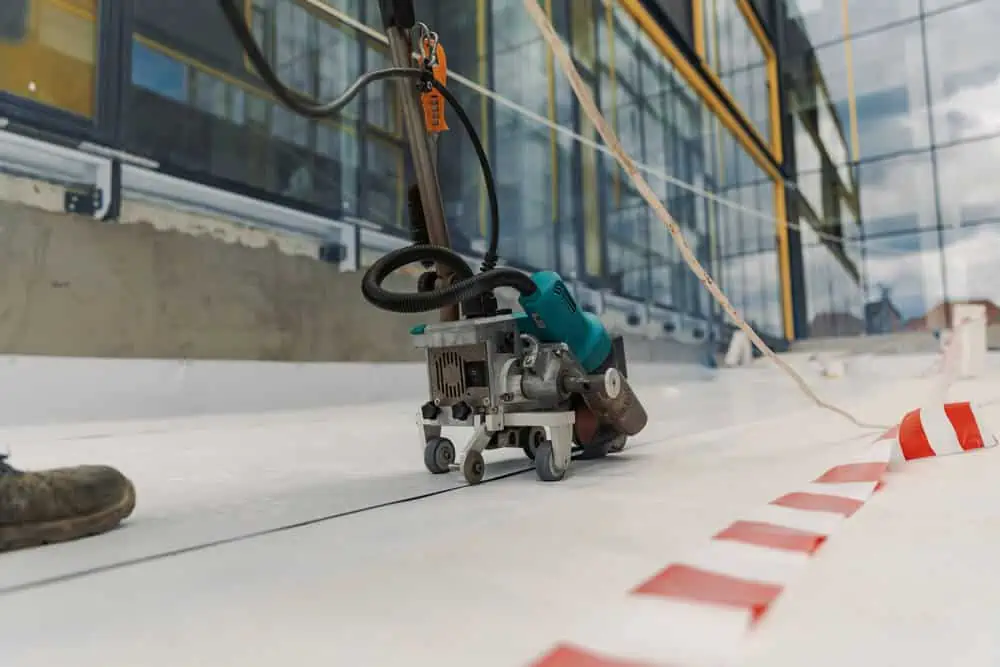

While PVC is popular for low-slope roofs, this system can become brittle over time, especially in cold climates, leading to cracking and leaks. Additionally, the installation process of PVC membranes typically requires heat-welded seams, which can be more labor-intensive than other attachment methods.

In summary, when choosing between TPO, EPDM, and PVC roofing systems, it’s essential to consider factors such as climate, building use, budget, and desired longevity. Each type has its strengths, so consulting with roofing professionals and considering specific project requirements is crucial for selecting the most suitable option.

To learn more about what single-ply roofing material is best for your commercial building, talk with the experts at TopKeyConstruction in Maryland, Northern Virginia, and Washington, D.C. We are happy to inspect your existing roof and give you a detailed roof replacement plan outlining your best options. Contact TopKey Construction today to learn more about single-ply systems.

Key Takeaways

- It’s important to consider the pros, cons, and costs of each single layer or ply membrane.

- TPO membranes are chemical resistant and flexible.

- EPDM roof membranes are durable, long-lasting, and easy to repair and maintain.

- PVC membranes offer excellent resistance to chemicals and oil and are fire resistant.